Improve Your Engineering Design by Selecting a Better Partner

The decision to outsource engineering design is usually not easy. But once that decision has been made, how do you choose the correct partner?

The decision to outsource engineering design is usually not easy. But once that decision has been made, how do you choose the correct partner?

5 Benefits of American Manufacturing

As product development managers and their teams complete the conceptual and design phases of their product, they begin looking into manufacturing. During this time, the pressure is often on these teams to keep costs down, which drives many to seek a manufacturing partner overseas, typically in a low cost country (LCC).

As product development managers and their teams complete the conceptual and design phases of their product, they begin looking into manufacturing. During this time, the pressure is often on these teams to keep costs down, which drives many to seek a manufacturing partner overseas, typically in a low cost country (LCC).

Why You Should Visit the Plant When Evaluating an RFP

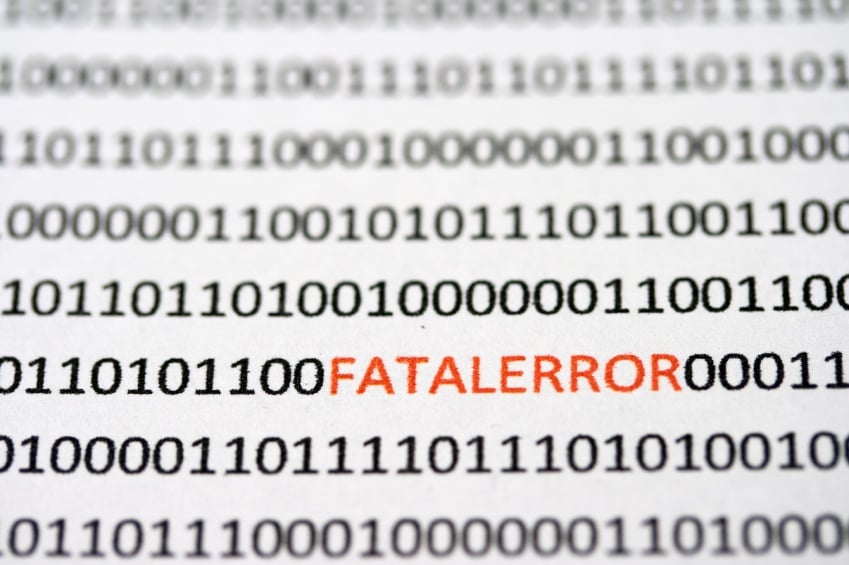

When evaluating a proposal by an engineering or manufacturing vendor, many questions about a vendor’s abilities can be answered with a site visit. A successful vendor invests in its facilities in an effort to be clean and well organized. This is an indicator of a business’s sense of order and attention to detail that will also be required for successful projects.

When evaluating a proposal by an engineering or manufacturing vendor, many questions about a vendor’s abilities can be answered with a site visit. A successful vendor invests in its facilities in an effort to be clean and well organized. This is an indicator of a business’s sense of order and attention to detail that will also be required for successful projects.

5 Characteristics of Quality Error Handling Systems

This is Part 2 of 2 of our Error Handling mini-series. You can download a PDF of both (extended) posts here in our Error Handling Handbook.

Read MoreError Handling and Resolving: What You Need to Know

This is Part 1 of 2 of our Error Handling mini-series. You can download a PDF of both (extended) posts here in our Error Handling Handbook.

Read MoreEnsuring Traceability with a Requirements Specification Template

The issue of traceability – the mapping of requirements to their products or systems and to each other – cannot be overlooked. Missing this component in your requirements specification can create problems throughout the development lifecycle, affecting architecture, design, and any subsequent modifications or evolutions to the requirements themselves.

The issue of traceability – the mapping of requirements to their products or systems and to each other – cannot be overlooked. Missing this component in your requirements specification can create problems throughout the development lifecycle, affecting architecture, design, and any subsequent modifications or evolutions to the requirements themselves.

What Are the Consequences of Poor Requirements Specifications?

Without a doubt, one of the most fundamental and important steps a product team can take is detailing out clear requirements for the manufacturing process. Having a comprehensive requirements specification sheet allows your CM partner to move forward and do what they do best - get products built on time and on budget.

Without a doubt, one of the most fundamental and important steps a product team can take is detailing out clear requirements for the manufacturing process. Having a comprehensive requirements specification sheet allows your CM partner to move forward and do what they do best - get products built on time and on budget. Balancing Sustainability with Quality Manufacturing

Whether on a political, economic, or environmental level, the notion of manufacturers altering their processes to be more sustainable - yet still emphasizing quality manufacturing - is always in the news. Frequent studies come out analyzing the current state of sustainable manufacturing and recommendations are made, and many contract manufacturers learn to adapt, both in order to properly align with regulations and to encourage sustainability throughout the manufacturing process.

Whether on a political, economic, or environmental level, the notion of manufacturers altering their processes to be more sustainable - yet still emphasizing quality manufacturing - is always in the news. Frequent studies come out analyzing the current state of sustainable manufacturing and recommendations are made, and many contract manufacturers learn to adapt, both in order to properly align with regulations and to encourage sustainability throughout the manufacturing process.

Protecting Your Intellectual Property During the Development

The RFP evaluation process is designed to clarify many aspects of potential partnerships and deliverables – the quality of the vendor, the scope of the project, and the outcomes on which success will be measured.

The RFP evaluation process is designed to clarify many aspects of potential partnerships and deliverables – the quality of the vendor, the scope of the project, and the outcomes on which success will be measured.

6 Ways to Verify Requirements Specifications

When writing perfect requirements for your product, there is a lot of ground to cover. After you have clearly specified your requirements, you still need to take the all important step of verifying them. A requirement must be stated such that there is a reasonable and cost-effective process by which to ensure the product or system meets the requirement.

When writing perfect requirements for your product, there is a lot of ground to cover. After you have clearly specified your requirements, you still need to take the all important step of verifying them. A requirement must be stated such that there is a reasonable and cost-effective process by which to ensure the product or system meets the requirement.

4 Tips to Get New Products to Market Faster

“Time is money.” That phrase may not be more true than in the fields of product development, engineering, and manufacturing. Lapses and delays don’t just cause a minor inconvenience here - rather, every day you fall behind schedule can mean lost revenue.

“Time is money.” That phrase may not be more true than in the fields of product development, engineering, and manufacturing. Lapses and delays don’t just cause a minor inconvenience here - rather, every day you fall behind schedule can mean lost revenue.

Whether you are launching a consumer product for the IoT, or if you are looking to produce a electronic part for a bigger end-product, coming in on time and under cost is essential to your long-term success. Here are four of the most common challenges companies run into during this process, and how you can optimize your way to a successful launch.

Read MoreHow to Find the Right Technology Partner For Your Company

One of the biggest challenges a product development company encounters is a lack of in-house resources required to solve a problem. This can range from the obvious (product manufacturing) to the more specific needs (software error handling), but when a company doesn't have the needed staff, time, or resources to move forward, they need to find and select a strong technology partner.

One of the biggest challenges a product development company encounters is a lack of in-house resources required to solve a problem. This can range from the obvious (product manufacturing) to the more specific needs (software error handling), but when a company doesn't have the needed staff, time, or resources to move forward, they need to find and select a strong technology partner.

One of the Biggest Myths About Product Development

When bringing a new product to market, it is vital for decision-makers to sift through the noise and focus in on what brings the most value to the product. Unfortunately, those in product development often tend to correlate added value with added features, so they try to include as many features as possible - thus overcomplicating the product.

When bringing a new product to market, it is vital for decision-makers to sift through the noise and focus in on what brings the most value to the product. Unfortunately, those in product development often tend to correlate added value with added features, so they try to include as many features as possible - thus overcomplicating the product.

Evaluating an Engineering and Manufacturing RFP? Look for Maturity

There are many KPIs to consider when evaluating an engineering or manufacturing RFP. Related to years in business and number of senior experts on staff, is the indicator of mature systems – processes and systems that have been seasoned over time to efficiently and predictably produce desired outcomes. Mature processes create historic data that is continually updated. Bugs have been detected. Problems have been anticipated, and results can be counted on.

There are many KPIs to consider when evaluating an engineering or manufacturing RFP. Related to years in business and number of senior experts on staff, is the indicator of mature systems – processes and systems that have been seasoned over time to efficiently and predictably produce desired outcomes. Mature processes create historic data that is continually updated. Bugs have been detected. Problems have been anticipated, and results can be counted on.

How to Optimize Your Product Manufacturing (5 Tips)

When it comes to the actual production or manufacturing of your product, chances are you know just how important timing and quality are. Unfortunately, many projects run into issues due to oversights during the early stages of product development, and companies can become frustrated with delays and new costs.

When it comes to the actual production or manufacturing of your product, chances are you know just how important timing and quality are. Unfortunately, many projects run into issues due to oversights during the early stages of product development, and companies can become frustrated with delays and new costs.

4 Things to Consider in a Contract Manufacturing Partner

Finding the right contract manufacturing partner for your product can be much more difficult than you would think. On paper, the concept is simple: who can make this product for the lowest price, or, who can produce this product the quickest? Often, it is a mix of both of these things. The truth is that while cost and timeline are vital to success, there are some other attributes that you need to look for in order to see the best return possible.

Finding the right contract manufacturing partner for your product can be much more difficult than you would think. On paper, the concept is simple: who can make this product for the lowest price, or, who can produce this product the quickest? Often, it is a mix of both of these things. The truth is that while cost and timeline are vital to success, there are some other attributes that you need to look for in order to see the best return possible.

What You Need to Know About Your Product Development Strategy

Without argument, one of the most important elements of a successful product development strategy is having a blueprint for success. Both in theory and quite literally, product development teams need to have a clear plan in place - something that specifies their project requirements and timelines throughout the process.

Without argument, one of the most important elements of a successful product development strategy is having a blueprint for success. Both in theory and quite literally, product development teams need to have a clear plan in place - something that specifies their project requirements and timelines throughout the process.

4 Ways Product Development Companies Can Improve Testing

For product development companies, testing any process or device can be time consuming and expensive. The need to perform accurate and repeatable testing across multiple components only adds to the time and resources required of product developers. Manual testing can take hours, and often results in inconsistencies and inaccuracies based on the range of technologies used and the skills of the tester.

For product development companies, testing any process or device can be time consuming and expensive. The need to perform accurate and repeatable testing across multiple components only adds to the time and resources required of product developers. Manual testing can take hours, and often results in inconsistencies and inaccuracies based on the range of technologies used and the skills of the tester.

So how can product development companies reduce test time while increasing accuracy?

The solution is in four key areas:

- Establish formal procedures that are accurate, flexible, and consistent – but also easily understood and performed.

- Collect and measure meaningful data using a controlled, purposeful, predictable means.

- Store data securely and accurately and make it easily accessible for presentation and analysis.

- Design a tester experience that is consistent across multiple testers, across multiple skill sets. The testing interface must be user-friendly and intuitive. Complicated systems and hard-to-follow input instructions invite confusion and can compromise data.

The Importance Of Requirements Specifications

You have an idea or a need for a test solution. You know exactly what it is supposed to be accomplished and how it will help meet your business goals. You plan meetings with qualified contractors during which you explain your need and ask for quotes.

You have an idea or a need for a test solution. You know exactly what it is supposed to be accomplished and how it will help meet your business goals. You plan meetings with qualified contractors during which you explain your need and ask for quotes.

In the meeting, you clearly explain that the solution should:

- Capture the name of the operator who runs the test.

- Allow the operator to enter information about the test article.

- Perform automated testing of the article per a list of parameters and pass/fail criteria supplied in a spreadsheet.

- Log the operator, test article information, and pass/fail criteria.

You obtain quotes, cut the purchase order, and work commences. The solution is created and the contractor wants to meet with you for demonstration and delivery.

That’s when the trouble begins.

Read MoreKeeping Up With Change in Product Development

The only thing you can count on is change. That’s especially true in the world of product and system development. Staff, schedules, priorities, competition, and resources all impact requirements specifications and can drive changes at any time – and at multiple times – throughout the development lifecycle.

The only thing you can count on is change. That’s especially true in the world of product and system development. Staff, schedules, priorities, competition, and resources all impact requirements specifications and can drive changes at any time – and at multiple times – throughout the development lifecycle.

So if you are tasked with leading the charge for your company's product development, it is vital that you stay (or become) dynamic - especially when it comes to your requirements specificiations.

Read MoreLooking for a Manufacturing Partner? Their Work Starts with the RFP

When selecting an engineering or manufacturing vendor, it is common for companies to identify project goals and the overall desired approach, and then issue an RFP.

When selecting an engineering or manufacturing vendor, it is common for companies to identify project goals and the overall desired approach, and then issue an RFP.

For companies, the real “work” begins when the proposals come in and they begin the evaluation and selection process and the project kicks off. But for quality vendors who are knowledgeable and experienced, work begins when they first see the RFP.

Read MoreHow Does a Modbus Master and Slave Work?

Modbus is an industrial communication protocol that has been around since 1979.

Modbus is an industrial communication protocol that has been around since 1979.

Originally developed to connect programmable logic controllers together, Modbus has become a de facto standard for communicating between industrial equipment.

How does a Modbus master and slave work? Modbus is a master/slave multidrop protocol. The master initiates all communication transactions. Each slave has a unique id, responding to the master only when addressed by the master.

Tricky Timing Requirements

Although Modbus is a simple communication protocol, its timing requirements can be difficult to meet in an embedded system with other strict timing requirements.

Recently I designed a custom industrial controller requiring both modbus master and slave support. The controller had to communicate with Modbus slaves on one serial port while simultaneously responding to a plc master on another serial port.

Read MoreEmbedded Control System with Data Visualization

When it comes to high quality embedded control systems, one is usually looking for a system that includes the following:

When it comes to high quality embedded control systems, one is usually looking for a system that includes the following:

- User Configuration

- Data Visualization

- Data Logging

- PC Connectivity

- Software Interface

The Importance of “Senior” in Selecting an Engineering Vendor

Part of Tecnova's RFP evaluation series -- helping businesses address vendor selection with confidence

There are many key performance indicators that can shed light on an engineering or manufacturing vendor’s ability to meet expectations put forth in their proposals and ensure overall project success. When evaluating an RFP from a potential project partner, one KPI is the skill and experience of the staff who will be executing the work. While a vendor’s junior engineers can do many lower-level tasks, it is important that senior engineers are on staff to do a significant amount of the work.

Read MoreEvaluating RFPs in Engineering or Manufacturing

Part of Tecnova's RFP evaluation series -- helping businesses address vendor selection with confidence

Part of Tecnova's RFP evaluation series -- helping businesses address vendor selection with confidence

This blog is the first in Tecnova's series on effectively evaluating proposals and selecting a quality, reputable electronic engineering or manufacturing vendor. The series outlines key indicators business leaders can use to evaluate a vendor’s ability and performance, and then choose an engineering or manufacturing partner that can address the project’s budget, scope, and complexities and deliver desired results.

Read MoreRequirements: 3 Ways to Make Sure Nothing Gets Missed

Part of Tecnova's requirements specification series -- helping businesses save money, time, and resources

Throughout this series, we've learned that writing solid requirements is the first, most critical step for product success. Yet, with developers juggling hundreds if not thousands of requirements, something inevitably slips through: A requirement is not addressed in development. Or it’s detected in implementation and testing, and it must be addressed in a later release. Other times the oversight is not noticed until the system is integrated, manufactured, or deployed. At that point, addressing the missing requirement and making necessary modifications can be even more costly and time consuming.

Read MoreRequirements: The Must-Haves vs. Nice-to-Haves

Part of Tecnova's requirements specification series -- helping businesses save money, time, and resources.

Read MoreThe 3 Cs of Requirements Specifications

Part of Tecnova's requirements specification series -- helping businesses save money, time, and resources

So far in this series, we've looked at the benefits of good requirements, the consequences of poor ones, and the common flaws found in so many of them. As this series continues, we'll look at what it takes to create quality requirements for successful products or systems – ones that deliver all necessary functionality on time and on budget.

So far in this series, we've looked at the benefits of good requirements, the consequences of poor ones, and the common flaws found in so many of them. As this series continues, we'll look at what it takes to create quality requirements for successful products or systems – ones that deliver all necessary functionality on time and on budget.

We may think requirements specifications need to be high grade As and Bs. But for truly effective requirements, it’s important to keep the Cs in mind: The 3 Cs of requirements specification -- correct, consistent, and clear.

Read MoreSolving the Most Common Problems with Requirements Specifications

Part of Tecnova's requirements specification series -- helping businesses save money, time, and resources

When businesses develop a new product, defining its requirements is the most important phase of the entire project. As we explored in the last installment of our series on requirements specification, problems that occur in this phase have a ripple effect, causing expensive complications in manufacturing and even product defects. Identifying and fixing problems in specifications is the first step in a successful product launch.

When businesses develop a new product, defining its requirements is the most important phase of the entire project. As we explored in the last installment of our series on requirements specification, problems that occur in this phase have a ripple effect, causing expensive complications in manufacturing and even product defects. Identifying and fixing problems in specifications is the first step in a successful product launch.

To improve your business's requirements, it can help to look at the most common characteristics of poor ones. If you can name the problem, it becomes possible to solve it.

Read MoreImproving Product Success Through Better Requirements Specifications

High-quality, effective products and systems start with a clear understanding of what the product or system needs to do. And that understanding has to be conveyed to multuple partners, including those in marketing, engineering, purchasing, and the executive suite.

High-quality, effective products and systems start with a clear understanding of what the product or system needs to do. And that understanding has to be conveyed to multuple partners, including those in marketing, engineering, purchasing, and the executive suite.

This blog is the first in Tecnova's series on requirements specifications. The series answers key questions about:

- The characteristics of good requirements specifications

- What happens when requirements specifications are poor

- How you can improve your company's performance by using a requirements specification template

Weighing the Pros and Cons of Overseas Manufacturing

Manufacturing in low cost countries (LCC) has been around for decades. The reason seems obvious: on the face of it, the lower cost of labor appears to allow competitive pricing of a company's products.

Manufacturing in low cost countries (LCC) has been around for decades. The reason seems obvious: on the face of it, the lower cost of labor appears to allow competitive pricing of a company's products.

But in evaluating whether or not to manufacture your product or its components overseas, there are important considerations to weigh, including hidden costs that occur with LCC manufacturing.

Read MoreLow-Cost Bluetooth Smart Module Lets Your Product Talk to iPhones

In a previous blog, I wrote about the advantages of using Android as a user interface for embedded software products. But as popular as Android devices are, companies embedding software in their products can't afford to ignore iOS: as of the end of 2013, there were 300 million iPhones in use, compared to 800 million Android devices.

In a previous blog, I wrote about the advantages of using Android as a user interface for embedded software products. But as popular as Android devices are, companies embedding software in their products can't afford to ignore iOS: as of the end of 2013, there were 300 million iPhones in use, compared to 800 million Android devices.

Making your embedded software product talk to iPhones and iPads used to be cost-prohibitive. But a relatively new Bluetooth smart module has put it within reach.

Read MoreHow to Develop Turnkey Test Solutions for Marine Product Development

For product manufacturers and development companies that test products for compliance, QA, and improved efficiencies, finding accurate and reliable test solutions can be a challenge. For starters, standard solutions that meet the precise needs of a specific industry are not always readily available out of the box. The testing environment, materials, and processes can be complex and constantly changing.

For example, testing may need automatic configuration, control, and failure detection of high-voltage dielectric materials. Other solutions have been sought to add new measurement capability with concern for code reuse, robust design, and long-term maintenance.

In this blog, I'll discuss some of the testing problems that can reduce productivity and profitability for product companies, and show how our automated test team overcame those problems to develop test solutions for marine product development.

Read More

3 Keys to No-Fail Communication Systems Engineering

No-fail communication systems are, by their nature, crucial. Whether you're NASA communicating with spacecraft or a police officer calling for backup, "no-fail" means it has to work or there can be major consequences. New technologies, such as indoor positioning systems used by campuses and hospitals, are emerging in communication systems engineering to help make these systems more effective.

No-fail communication systems are, by their nature, crucial. Whether you're NASA communicating with spacecraft or a police officer calling for backup, "no-fail" means it has to work or there can be major consequences. New technologies, such as indoor positioning systems used by campuses and hospitals, are emerging in communication systems engineering to help make these systems more effective.

Perhaps in no situation is reliable communications more important than in emergency management and response. Police, fire, and ambulances need a robust communications system that is nimble, dependable, and immediate. Emergency circumstances require the coordination of personnel from within and among departments, and response teams from multiple units often must work in concert to resolve difficult and dangerous situations. Communication systems are needed to ensure resources are in place to perform the correct tasks and to maintain the safety of all individuals involved.

Read MoreHow to Use Custom Desktop Software Development to Manage Your Data

Data management can be one of the most challenging tasks companies face today. There is more and more information, generated and accessed by multiple users across multiple platforms and network locations. Data may be in both an unstructured or semi-structured format, and exist in various forms including emails, presentations, pictures, and other files. Some companies also have data in the form of images, audio, and video.

Data management can be one of the most challenging tasks companies face today. There is more and more information, generated and accessed by multiple users across multiple platforms and network locations. Data may be in both an unstructured or semi-structured format, and exist in various forms including emails, presentations, pictures, and other files. Some companies also have data in the form of images, audio, and video.

Remote staff, BYOD, multiple file types, and various internal and external Cloud applications all add to the complexity and challenges of data management.

Many businesses are finding that off-the-shelf applications or standard file sharing such as Dropbox and Google Drive are not robust or searchable enough to deal with these complexities. Knowing that ineffective data management can lead to wasted staff time and money, they're turning to custom desktop software development for greater efficiencies and better performance both internally and externally.

Read MoreBreak Down Sales Barriers with Digital Electronics Design

Buying electronics either from a product catalog or online can be complicated. When customers can't tell what they're buying and whether it will be compatible with their systems and equipment, that creates barriers to sales for your business.

Buying electronics either from a product catalog or online can be complicated. When customers can't tell what they're buying and whether it will be compatible with their systems and equipment, that creates barriers to sales for your business.

Many products have multiple components and accessories with many combinations of product codes and parts numbers. In addition, some combinations of options may not be compatible, which is difficult for manufacturers to convey – and for customers to understand – from a catalog page or static web page.

Product companies must ask themselves, are they missing sales because of their own inventory systems?

Read MoreCutting the Greenhouse Effect: Automation Puts CO2 Separation in Reach

Global warming, mining and drilling, the greenhouse effect – they’re in the news all the time. The environment is something that's at the forefront of politics and our future, and efforts are being made in response. Countries are adopting stringent emission reductions and energy product development companies are always working to improve operations to meet not only federal regulations but society's expectations.

Global warming, mining and drilling, the greenhouse effect – they’re in the news all the time. The environment is something that's at the forefront of politics and our future, and efforts are being made in response. Countries are adopting stringent emission reductions and energy product development companies are always working to improve operations to meet not only federal regulations but society's expectations.

Where does engineering come in?

Engineering is at work for the environment in many ways. For example, for years, CO2 separation has been applied in oil and coal gasification and natural gas processing to reduce this greenhouse gas to levels acceptable by countries and regulatory agencies.

Sorbates can be used to “scrub” gaseous products, removing the unwanted CO2. However, naturally found sorbates have their limitations.

Read MoreMore Products 'Touch Cloud' with Embedded Custom Software Development

A decade ago, adding Ethernet to an embedded product was an expensive investment. Now, it can be done for $7.00 or less in hardware combined with embedded custom software development. What happened?

The number of transistors on integrated circuits has been doubling approximately every two years, as predicted by Moore’s Law. This has made it possible for IC manufacturers to embed Ethernet media access controllers into low-cost microcontrollers. Which, in turn, has made it possible to add Ethernet to an embedded product at a low hardware cost.

Now that the technology is within reach, manufacturers and product designers need to at least consider incorporating a cloud connection into every manufacture. Why?

Now that the technology is within reach, manufacturers and product designers need to at least consider incorporating a cloud connection into every manufacture. Why?

Can Android Communicate with Embedded Systems?

While buttons, LEDs, and character LCDs were sufficient for interfacing with the embedded systems of the past, future embedded systems will be more intelligent, configurable, and connected, requiring a new approach to the user interface. Modern users are accustomed to more advanced user interfaces, ones with touchscreens, and on-screen keyboards.

While buttons, LEDs, and character LCDs were sufficient for interfacing with the embedded systems of the past, future embedded systems will be more intelligent, configurable, and connected, requiring a new approach to the user interface. Modern users are accustomed to more advanced user interfaces, ones with touchscreens, and on-screen keyboards.

But LCDs and touchscreens add unwanted cost adders to embedded system products in the form of board cost, and software support. Luckily there are better and more cost effective ways to provide your embedded system with an easily programmable user interface.

Instead of building an embedded system with a LCD and touchscreen, why not take advantage of the LCD and touchscreen that most people carry in their pocket every day?

Read More