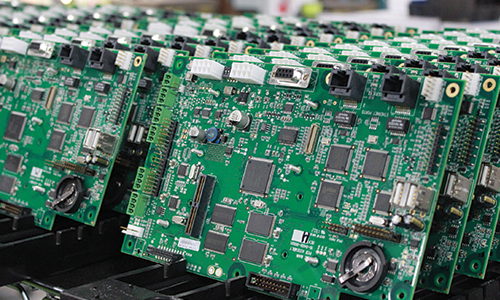

Printed Circuit Boards

- Manufacturing

- Printed Circuit Boards

Highly Skilled Instructors, Operators and Assemblers

- In-house J-STD-001 and IPC-A-610 Instructors who oversee a comprehensive internal training program

- Tecnova Electronics is one of the largest employers of trained specialists that meet IPC-A-610, Class III standards in the state of Illinois

Flexible Surface Mount Production Lines

- Automated solder paste screening equipment with in-line inspection system

- Multiple high speed / high accuracy pick and place systems for components as small as 0201, including BGA and microBGA

- Board sizes up to 20" x 18"

- Laser serial number marking system

Through-Hole Assembly Lines

- Automated Lead forming equipment. Tape and liquid masking processes

Quality Inspection Systems

- Automated Optical Inspection (AOI) to verify component and placement accuracy

- Solder Paste Inspection (SPI)

- In-house X-Ray inspection for BGA and component inspection

- In-Circuit Test (ICT) to verify shorts, opens, and component values

- Coordinated Measuring Machine (CMM) to verify mechanical dimensions

- Custom functional test fixtures for programming and performing functional testing

Cleanliness

- No-clean solder

- Ionic contamination testing for high impedance assemblies

Strict Process Control

- Climate controlled production facility with electro-static conductive epoxy flooring

- ESD controls throughout the manufacturing process

- Strict adherence to Moisture Sensitivity Level (MSL) handling practices and procedures

- Dedicated dry room for the storage and control of in-process PCB assemblies

Rugged Exposure Protection

- High accuracy, automated selective spray system for the application of acrylic or silicone based conformal coatings

- Automated epoxy dispensing equipment for protection against harsh environmental exposure