Complete Products

- Manufacturing

- Complete Products

Complete Products

Tecnova’s experienced workforce, along with its industry expertise, use of proven vendors, and constant ingenuity combine to produce finished goods you can rely on.

Our experienced Manufacturing Engineers will review your documentation to verify accuracy, and generate comprehensive Assembly Instructions for every step.

Fully vetted, and proven suppliers, will fabricate and machine parts to meet critical mechanical specifications.

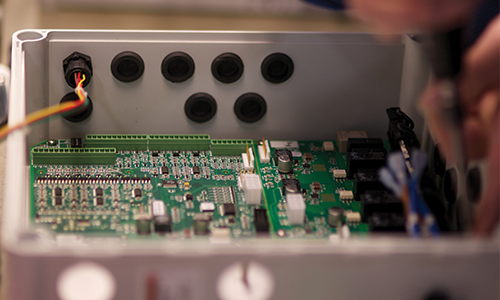

Each board, cable, control panel, and sub-assembly we build meets strict Quality Assurance

We use Automated Optical Inspection to verify part placement accuracy and solder integrity for surface mount boards. Also, we offer non-powered In-Circuit Test to detect shorts, opens and verify component values, or a powered, full functional test.

Rigorous inspections are performed at each stage of assembly to ensure quality.

Finished goods go through a final test and quality inspection prior to being boxed for shipment.

Extensive Capabilities to bring your Product to Market

- All members of our Production Team are trained through an in-house developed training program to IPC-610 and J-STD-001

- In-house engineering staff which is dedicated to supporting manufacturing and developing necessary assembly instructions

- In-house wire harness and cable assembly capabilities

- State-of-the-art production equipment and testing capabilities

- Pilot and production manufacturing

- We ship globally, and when needed we will design custom shipping boxes to ensure that your product arrives at its destination undamaged.

- Regular cost reduction strategies and component obsolescence reviews

From printed circuit boards to complex complete products, control panels and electronic box builds, Tecnova’s team of experienced assemblers and skilled technicians provide the quality and on-time delivery you should expect from your manufacturing partner.